Everything began in the mid-eighties in Karl-Josef-Schäfer's home kitchen: To manufacture a bend for a ventilation made of plastic, he heated a PVC tube in the oven and then formed it with a bicycle tube.

The result was impressive, and so Karl-Josef proudly demonstrated it to his former boss Horst Severyns. Both men quickly realized the necessity of founding a company which would develop machines for the production of bends - this was foundation date of HoKa (Horst & Karl).

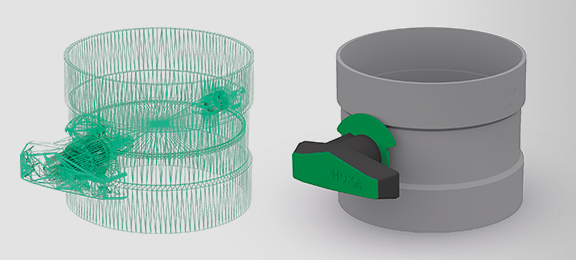

The developed blow pipe procedure was patented and is the central component of HoKa's manufacturing process to date. Today, the company is equipped with the latest in technology and markets its ventilation fittings of thermoplastics throughout the world.