Short Profile

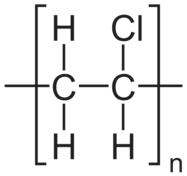

Polyvinylchloride, abbreviated Hard-PVC, is an unplasticised amorphous thermoplastic material. PVC is characterized by high chemical resistance and it is self extinguishing after withdrawal of an external flame. Additional characteristics of the material are its high strength, rigidity and dimensional stability. In the Ventilation area, PVC-U grey is primarily chosen for interior use.