Available in the materials:

| PVC | PVC white | PPs | PP-H | PE-HD | PP-EL-s | PVDF |

| PVC | PE-HD/PP-H/PPs/PP-EL-s/PVDF | |||

| Ø | L | min. s | L | min. s |

| 50 | 25 | 1,8 | 25 | 3,0 |

| 63 | 25 | 1,8 | 25 | 3,0 |

| 75 | 40 | 1,8 | 40 | 3,0 |

| 90 | 40 | 1,8 | 40 | 3,0 |

| 110 | 40 | 1,8 | 40 | 3,0 |

| 125 | 40 | 1,8 | 40 | 3,0 |

| 140 | 40 | 1,8 | 40 | 3,0 |

| 160 | 40 | 1,8 | 40 | 3,0 |

| 180 | 40 | 1,8 | 40 | 3,0 |

| 200 | 40 | 1,8 | 40 | 3,0 |

| 225 | 40 | 1,8 | 40 | 3,5 |

| 250 | 40 | 2,0 | 40 | 3,5 |

| 280 | 50 | 2,3 | 50 | 3,5 |

| 315 | 50 | 2,5 | 50 | 4,0 |

| 355 | 50 | 2,9 | 50 | 4,0 |

| 400 | 50 | 3,2 | 50 | 4,5 |

| 450 | 50 | 3,6 | 50 | 5,0 |

| 500 | 50 | 4,0 | 50 | 5,0 |

| 560 | - | - | 60 | 5,0 |

| 600 | 60 | 5,0 | 60 | 6,0 |

| 630 | - | - | 70 | 6,0 |

| 700 | 70 | 6,0 | 70 | 6,0 |

| 710 | - | - | 80 | 6,0 |

| 800 | 80 | 8,0 | 80 | 8,0 |

| 900 | 90 | 8,0 | 90 | 8,0 |

| 1000 | 100 | 10,0 | 100 | 10,0 |

| 1200 | 120 | 12,0 | 120 | 12,0 |

| 1250 | 130 | 12,0 | 130 | 12,0 |

| PVC from Ø 700 mm, PE-HD/PP-H/PPs from Ø560 mm, PP-EL-s and PVDF from Ø 450 mm are manufactured as segmental bends. | ||||

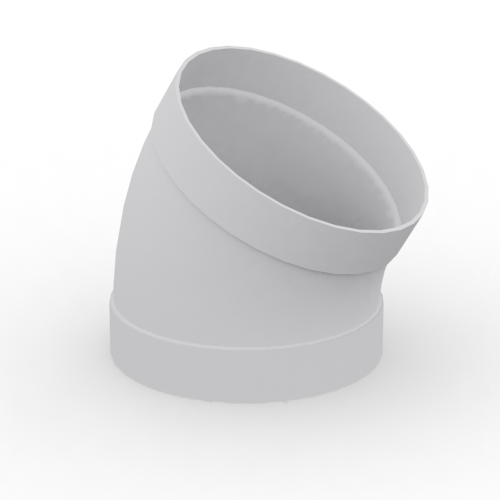

HOKA PVC 30° bend with socket plastic fitting round with interior stop for connecting pipes in an exhaust system by welding process. Socket inside diameter on the basis of DIN 8062, R=D manufacturing process: Ø 50 to 400 mm injection moulding, Ø 450 to 600 mm patented blow moulding, from Ø 700 segment welded. Possible negative overpressure upon request according to mechanical, chemical, and thermal load.

HOKA PVC white 30° bend with socket plastic fitting round with interior stop for connecting pipes in an exhaust system by welding process. Socket inside diameter on the basis of DIN 8062, R=D manufacturing process: Ø 50 to 400 mm injection moulding, Ø 450 to 600 mm patented blow moulding, from Ø 700 segment welded. Possible negative overpressure upon request according to mechanical, chemical, and thermal load.

HOKA PE-HD 30° bend with socket plastic fitting round with interior stop for connecting pipes in an exhaust system by welding process. Socket inside diameter on the basis of DIN 8074, R=D manufacturing process: Ø 50 to 400 mm injection moulding, Ø 450 to 500 mm patented blow moulding, from Ø 560 segment welded. Possible negative overpressure upon request according to mechanical, chemical, and thermal load.

HOKA PP-H 30° bend with socket plastic fitting round with interior stop for connecting pipes in an exhaust system by welding process. Socket inside diameter on the basis of DIN 8077, R=D manufacturing process: Ø 50 to 400 mm injection moulding, Ø 450 to 500 mm patented blow moulding, from Ø 560 segment welded. Possible negative overpressure upon request according to mechanical, chemical, and thermal load.

HOKA PP (flame resistant) 30° bend with socket plastic fitting round with interior stop for connecting pipes in an exhaust system by welding process. Socket inside diameter on the basis of DIN 8077, R=D manufacturing process: Ø 50 to 400 mm injection moulding, Ø 450 to 500 mm patented blow moulding, from Ø 560 segment welded. Possible negative overpressure upon request according to mechanical, chemical, and thermal load.

HOKA PVDF 30° bend with socket plastic fitting round with interior stop for connecting pipes in an exhaust system by welding process. Socket inside diameter on the basis of DIN ISO EN 10931, R=D manufacturing process: Ø 50 to 400 mm injection moulding. Possible negative overpressure upon request according to mechanical, chemical and thermal load.

HOKA PP-EL-s 30° bend with socket plastic fitting round with interior stop for connecting pipes in an exhaust system by welding process. Socket inside diameter on the basis of DIN 8077, R=D manufacturing process: Ø 50 to 400 mm injection moulding, Ø 450 to 500 mm patented blow moulding, from Ø 560 segment welded. Possible negative overpressure upon request according to mechanical, chemical, and thermal load.